1. Introduction

The graphitization furnace is one of the most important equipment in the manufacturing process of graphite products, and its operation directly affects the quality and performance of the final product. This article will deeply explore the operating principle, key components and process flow of the graphitization furnace, aiming to help readers fully understand the role and technical details of this key equipment in the production of graphite products.

2. Basic principles of graphitization furnace

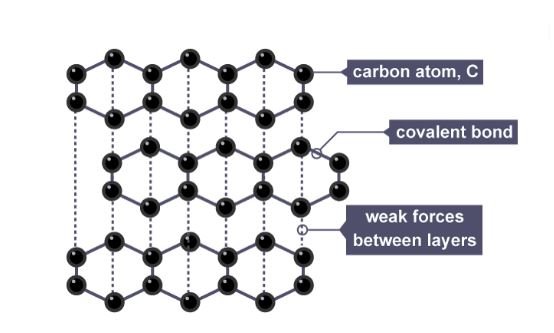

The graphitization furnace is mainly used to treat the original graphite powder or graphite sheet at high temperature to crystallize it into high-purity and high-crystallinity graphite products. Its basic principle can be summarized as the rearrangement of carbon atoms and lattice reconstruction during the heat treatment process, as well as the thermodynamic equilibrium under atmosphere control.

3. Key components of the graphitization furnace

3.1 Heating chamber (furnace)

The heating chamber of the graphitization furnace is usually made of high-temperature resistant materials, such as graphite, silicon carbide, etc., to withstand thermal shock and chemical corrosion in high-temperature environments. Heating elements (resistance wires, electric heaters, etc.) are provided inside the heating chamber to provide a high-temperature environment.

3.2 Temperature Control System

The temperature control system is a crucial part of the graphitization furnace, which is used to accurately control the temperature in the furnace. Advanced temperature sensors (such as thermocouples or infrared thermometers) and PID controllers are usually used to adjust the power of the heating elements to maintain the set process temperature curve.

3.3 Atmosphere Control System

The atmosphere in the graphitization furnace has an important influence on the quality of the final product. The atmosphere control system controls the composition of the gas entering the heating chamber (such as inert gases such as nitrogen or argon) to adjust the oxidizing or reducing nature of the atmosphere in the furnace, thereby affecting the formation and structural properties of graphite crystals.

4. Process flow of graphitization furnace

4.1 Preparation before heat treatment

Before putting the graphite raw material into the graphitization furnace, it is usually necessary to pre-treat the powder or cut and shape the graphite sheets to facilitate the subsequent heat treatment process.

4.2 Heating stage

Once ready, the graphitization furnace starts the heating system and gradually heats up to the set heat treatment temperature. During the heating process, temperature control is critical to ensure that the graphite raw materials are evenly heated and crystallized in a high temperature environment.

4.3 Maintenance and cooling stage

After reaching the target temperature, the graphitization furnace will maintain a certain period of heat treatment duration to ensure the complete transformation and stabilization of the graphite crystals. Subsequently, according to the specific product requirements, gradual cooling or rapid cooling can be performed to fix the crystal structure and physical properties of the graphite.

5. Application and development trend of graphitization furnace

5.1 Application field

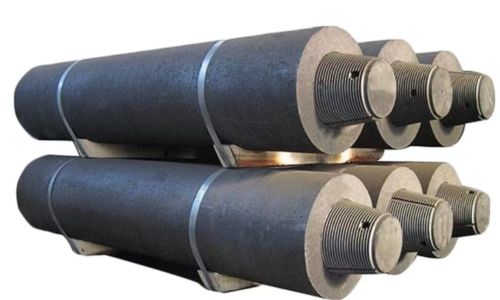

Graphitization furnaces are widely used in graphite electrodes, graphite cathode materials, graphite pyrolysis materials and other fields. Especially in lithium-ion batteries, supercapacitors, photovoltaic cells and semiconductor industries, the demand for high-performance graphite products is increasing.

5.2 Technology trend

With the advancement of science and technology and process optimization, the control accuracy, energy efficiency and safety of graphitization furnaces are constantly improving. The new graphitization furnace can not only achieve higher temperature and more stable atmosphere control, but also gradually develop towards intelligence and automation to meet increasingly complex production needs and environmental protection standards.

6. Conclusion

The graphitization furnace is the core equipment in the graphite product manufacturing process. Its operating principle and process flow have an important impact on the quality and performance of the final product. By deeply understanding the key components, process flow and application areas of the graphitization furnace, it can help manufacturers and technicians better master the operation technology and optimization methods of the graphitization furnace, thereby improving production efficiency and product quality, meeting market demand and technological innovation challenges.