Intrinsic Thermal Conductivity

Graphite exhibits exceptional heat transfer capabilities among carbon allotropes, with in-plane thermal conductivity reaching 1500-2000 W/(m·K)—significantly surpassing copper (~400 W/(m·K)). This originates from:

-

Delocalized π-electron system via sp² hybridization

-

Rigid lattice structure with strong covalent bonds

-

Phonon-dominated heat transfer mechanism (~4300 W/(m·K) at room temperature)

Key Thermophysical Parameters

| Property | Value Range | Physical Significance |

|---|---|---|

| CTE | 1.0×10⁻⁶ K⁻¹ | Superior dimensional stability at high temperatures |

| Thermal Shock Resistance | ΔT>1000℃ | Synergy of low elastic modulus (≈10 GPa) and high strength |

| Specific Heat Capacity | 706.9 J·kg⁻¹·K⁻¹ | Energy storage per unit mass |

| Sublimation Point | 3650℃ (1 atm) | Direct solid-gas phase transition |

| Operating Range | -200~3300℃ | Structural integrity in inert environments |

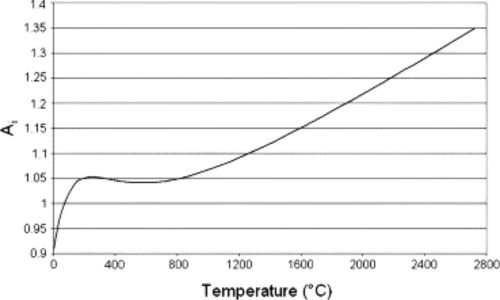

Temperature Response Mechanisms

-

Enhanced Electron Mobility (100-2500℃)

-

Carrier concentration increases to 10¹⁹ cm⁻³

-

Electrical conductivity boost promotes heat transfer

-

-

Lattice Vibration Evolution

-

Low-T region (<-50℃): Phonon scattering dominance

-

High-T region (>2000℃): Restricted Umklapp processes

-

Oxidation Threshold (>427℃)

Oxidation rate in air:

Industrial Application Matrix

| Sector | Core Function | Critical Parameters |

|---|---|---|

| Electronics Cooling | Thermal interface material | κ∥>1500 W/(m·K) |

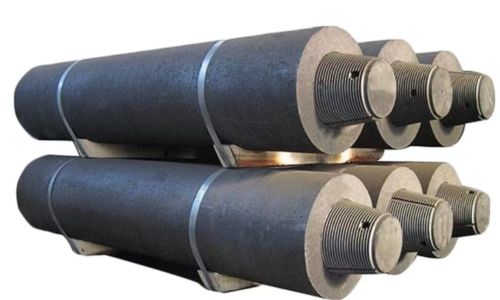

| Arc Steelmaking | Electrodes | Withstands 3000℃ plasma |

| Aerospace TPS | Thermal protection | CTE≈0.8×10⁻⁶/K (axial) |

| Crystal Growth | Crucibles | Purity>99.999% |

| Cryogenic Engineering | Seals | Maintains ductility at -269℃ |

Advanced Thermal Management Technologies

-

Highly Oriented Pyrolytic Graphite (HOPG)

-

Thermal anisotropy ratio: κ∥/κ⊥≈200

-

Applied in concentrated PV cooling

-

-

Graphene-Reinforced Composites

-

5wt% addition increases κ by 300%

-

Thermal diffusivity: 120 mm²/s

-

-

Nuclear Reactor Moderators

-

Neutron absorption cross-section: 3.5 mbarn

-

High-T stability (>2500℃ continuous operation)

-

Performance Boundaries

-

Oxidation Prevention: Vacuum <10⁻³ Pa or argon atmosphere

-

Low-T Brittleness Threshold: Isotropic graphite at -170℃

-

Radiative Heat Limit: 7.3 MW/m² blackbody radiation at 3000℃

-

Thermal Cycling Life: >5000 cycles at ΔT=1500℃ (aviation brake standard)

Experimental data: Single-crystal graphite reaches peak κ of 4000 W/(m·K) along (002) plane at 80K, attributed to extended phonon mean free path at cryogenic temperatures.

Material Selection Criteria

-

High-T Applications (>2000℃)

-

Prefer isostatically pressed graphite (density>1.85 g/cm³)

-

Open porosity <15%

-

-

Heat Exchange Systems

-

Thermal anisotropy ratio >100

-

Ash content <200 ppm

-

-

Extreme Environment Seals

-

Fluoropolymer impregnation for densification

-

Thermal shock resistance factor >500 W/m

-

This thermal analysis provides theoretical foundations for material selection in high-temperature systems, particularly critical for nuclear components, hypersonic vehicle TPS, and third-generation semiconductor cooling.