Material Composition and Characteristics

Carbon graphite is a synthetic composite material formed by combining an amorphous carbon matrix with flake graphite, exhibiting a steel-gray to deep black gradient. Its core properties derive from a unique dual-phase structure:

| Property Category | Performance Specifications | Mechanism |

|---|---|---|

| Thermal Stability | Oxidative (200-600°C) Inert (≤3000°C) Cryogenic (-270°C) |

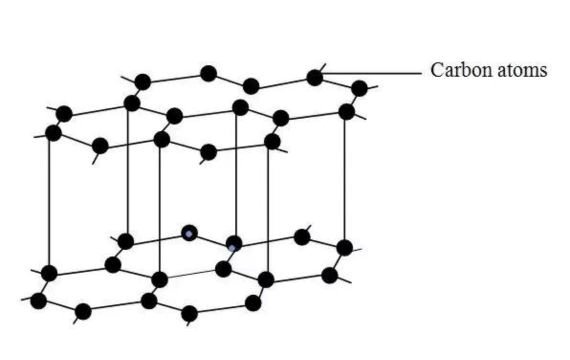

Stability of sp²-hybridized carbon network |

| Corrosion Resistance | Resists petroleum derivatives, SO₂ | Covalent-bonded hexagonal lattice |

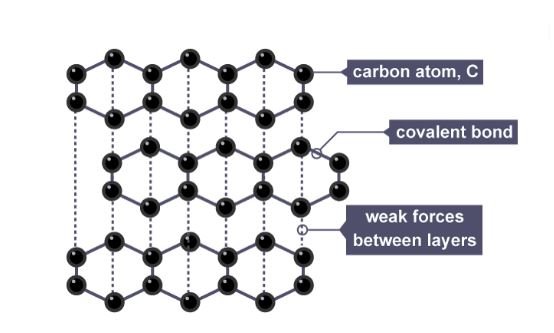

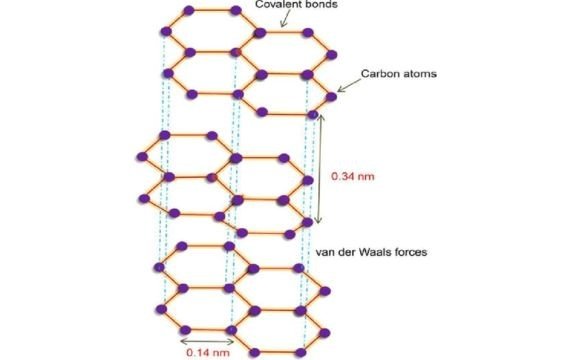

| Self-Lubrication | Dry friction coefficient: 0.08-0.15 | Weak van der Waals forces between graphene layers |

| Controlled Porosity | Porosity: 15-30% | Pyrolytic volatilization creating porous network |

Advanced Manufacturing Process

-

Raw Material Compounding

-

Amorphous carbon (Vickers hardness: 150-300 HV)

-

Natural flake graphite (particle size: 20-80μm)

-

Coal tar pitch binder (softening point: 90-110°C)

-

-

Forming & Carbonization

-

Isostatic pressing (100-200 MPa)

-

Carbonization at 800-1200°C (N₂ atmosphere)

-

Mass reduction: 15-25% (volatile removal)

-

-

Graphitization Enhancement

-

Acheson furnace treatment (2500-3000°C)

-

Functional impregnation:

-

Metal impregnation (enhances thermal conductivity)

-

Resin filling (improves corrosion resistance)

-

Solid lubricants (optimizes tribological properties)

-

-

Comparative Performance Analysis

| Parameter | Carbon Graphite | Pure Graphite |

|---|---|---|

| Density (g/cm³) | 1.7-1.9 | 2.1-2.3 |

| Compressive Strength (MPa) | 80-150 | 20-50 |

| CTE (×10⁻⁶/K) | 2.5-5.5 | 0.5-4.5 |

Engineering Advantages

-

Extreme Temperature Adaptability: Maintains dimensional stability (CTE<5.5×10⁻⁶/K) from -270°C to 3000°C

-

Self-Sustaining Lubrication: Dynamic transfer film reduces wear rate to 10⁻⁶ mm³/N·m magnitude

-

Chemical Inertness: Stable in pH 0-14 environments (excluding strong oxidizers)

-

Precision Machinability: Achievable tolerance: ±0.005 mm

Industrial Applications

-

Fluid Control Systems: Ball valve seats (cryogenic service)

-

Rotating Machinery Components:

-

Centrifugal pump impellers (ANSI/API 610)

-

Compressor bearings (ISO 10438)

-

-

Specialized Sealing Elements:

-

Mechanical seal rings (API 682 standard)

-

Nuclear-grade graphite seals

-

-

Wear-Resistant Components:

-

Wafer handling carriers

-

High-temperature guide plates

-

Graphite-structure

Material Enhancement Pathways

-

Nano-Reinforcement: 5% graphene addition increases mechanical strength by 40%

-

Composite Impregnation: Copper + MoS₂ dual-phase impregnation elevates PV limit to 5.0 MPa·m/s

-

Surface Functionalization: CVD silicon carbide coating enables 800°C oxidation resistance

Industrial data indicates carbon graphite components extend service life by 300% in abrasive media pumps compared to conventional materials.

Material Selection Guidelines

| Operating Condition | Recommended Grade |

|---|---|

| High load (>50 MPa) | Bronze-impregnated CB series |

| Highly corrosive environments | PTFE-impregnated CGW type |

| Food/Pharmaceutical grade | FDA-compliant resin impregnation |

This composite material integrates graphite’s self-lubrication with amorphous carbon’s mechanical strength, serving as an irreplaceable engineering solution in aerospace, energy equipment, and precision manufacturing sectors.