In view of the breakage problem of graphite electrodes in steelmaking, the analysis was conducted from different perspectives of the intrinsic quality of ultra-high power graphite electrodes and smelting process operations, which can be summarized into the following three categories: operational reasons, control reasons, and electrode quality reasons.

First: Reasons for operation

(1) The collapsing material breaks the electrode.

If the scrap steel in the furnace has formed a bridge structure during the smelting process, especially when it is close to melting, the short arc operation for a long time will produce a large lateral impact force of collapse; when an electrode becomes loose somewhere, the junction will Due to the thinning of the oxidation-accelerating electrode, the probability of breakage here is also high.

(2) Resonance breaks the electrode.

The electrode will definitely vibrate under the action of electromagnetic force during the smelting process. If the mechanical vibration frequency of the electrode column is close to or synchronized with the electromagnetic force vibration frequency, the electrode will resonate and easily lead to fatigue breakage of the electrode.

(3) Irregular clamping operation leads to broken electrodes.

If the electrode and the holder cannot be kept vertical, the electrode will have an additional horizontal force component; if there are foreign objects on the clamping surface, stress concentration will easily occur at the clamping point; these poor operations can easily cause the electrode to break during the smelting process.

Second: control reasons

(1) There are non-conductive objects under the electrodes in the furnace.

During the process of electrode driving down, after the lower end of the electrode comes into contact with a non-conductive object, the electrode regulator cannot accurately judge that the electrode has dropped to the position, but the electrode regulator controls the electrode to continue to fall, causing the electrode and scrap steel to be squeezed and broken longitudinally.

(2) The electrode regulator cannot detect the decrease in the phase-to-ground voltage.

If the connection line between the neutral point of the voltage transformer and the bottom shell of the electric furnace is disconnected, the electrode regulator cannot detect the decrease in the phase-to-ground voltage and cannot judge that the electrode has dropped to the position, causing the electrode regulator control electrode to continue to drop, causing the electrode to Extruded and broken with scrap steel.

(3) The electrode regulator cannot detect the arc current

If the electrode regulator cannot detect the arc current after the electrode arcs, or the arc current is very small, the electrode regulator will control the second phase electrode to continue to fall, which will cause the second phase electrode to be extruded and broken by the scrap steel.

(4) The hydraulic drive mechanism of the electrode regulator is in abnormal condition.

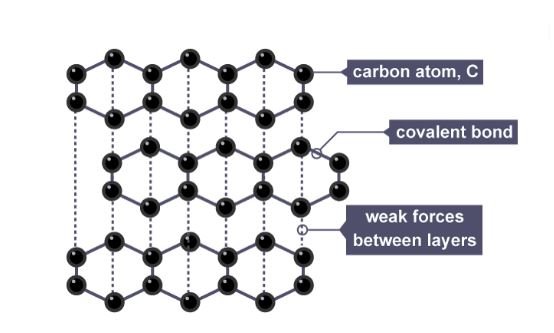

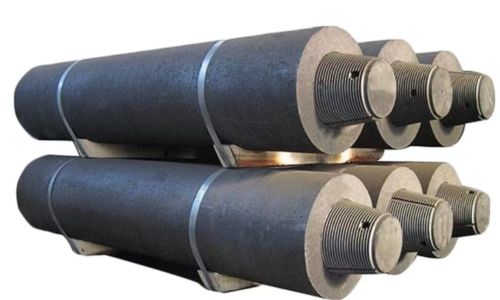

Third: Reasons for the internal quality of the electrode

(1) Reasons for joint breakage;

(2) Reasons for electrode breakage;