1. Fundamental Definitions

Synthetic Graphite

Manufactured through pyrolysis of hydrocarbon precursors (petroleum coke, coal tar pitch) followed by graphitization at >2500°C. Features controlled crystallinity (typically 80-90% graphitization degree) and anisotropic properties.

Natural Graphite

Naturally occurring mineral formed through metamorphic processes. Classified into three structural variants:

-

Flake (hexagonal plates, 85-98% C)

-

Vein (needle-like crystals, 90-99% C)

-

Amorphous (microcrystalline, 70-85% C)

2. Manufacturing Process Comparison

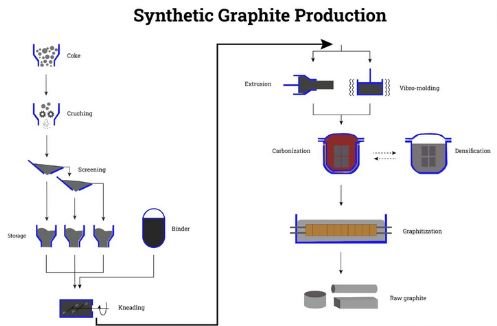

Synthetic Graphite Production

-

Feedstock Preparation:

-

Petroleum coke (90-95% C)

-

Coal tar pitch binder (CTP, 50-55% C)

-

-

Forming:

-

Isostatic pressing (200-300MPa)

-

Extrusion molding

-

-

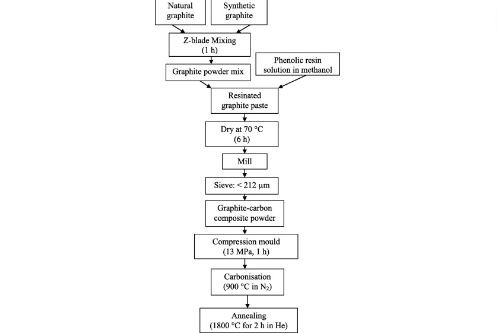

Carbonization:

-

800-1200°C in inert atmosphere

-

Volatile removal (15-25% mass loss)

-

-

Graphitization:

-

Acheson furnace (2500-3000°C)

-

Resistive heating for 2-3 weeks

-

Key Parameters:

-

Bulk density: 1.7-1.9 g/cm³

-

Resistivity: 8-12 μΩ·m

Natural Graphite Processing

-

Mining:

-

Open-pit (flakes) vs underground (vein)

-

Global reserves: Turkey (28%), China (22%), Brazil (21%)

-

-

Beneficiation:

-

Froth flotation (up to 95% C recovery)

-

Acid leaching (HF/HNO₃ for 99.9% purity)

-

-

Size Classification:

-

Coarse flakes (>300μm)

-

Micronized powder (<10μm)

-

3. Structural & Property Comparison

Crystalline Characteristics

| Parameter | Synthetic | Natural Flake |

|---|---|---|

| d₀₀₂ Spacing (Å) | 3.354-3.370 | 3.353-3.356 |

| Crystallite Size Lₐ (nm) | 50-150 | 200-1000 |

| Degree of Graphitization (%) | 80-90 | 95-99 |

Physical Properties

| Property | Synthetic | Natural |

|---|---|---|

| Thermal Conductivity (W/m·K) |

-

In-plane | 150-400 | 300-700

-

Cross-plane | 5-10 | 5-8

Electrical Resistivity (μΩ·m) | 8-15 | 5-40

Coefficient of Friction | 0.1-0.15 | 0.15-0.4

Ash Content (%) | 0.1-0.5 | 1.5-15

BET Surface Area (m²/g) | 0.5-5 | 5-20

Chemical Behavior

-

Oxidation Resistance:

Synthetic: Onset 450°C (air)

Natural: Onset 400°C (air) -

Acid Resistance:

Both stable in non-oxidizing acids (HCl, H₂SO₄)

Natural shows 20% higher dissolution in HNO₃

4. Advanced Form Comparison

| Form Type | Synthetic Variants | Natural Variants |

|---|---|---|

| Primary Forms | Isotropic graphite | Flake graphite |

| Pyrolytic graphite | Vein graphite | |

| Carbon fiber composites | Amorphous graphite | |

| Nanoforms | Graphene nanoplatelets (3-10nm) | Exfoliated graphene oxide |

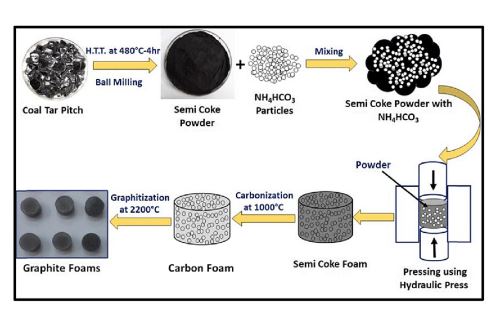

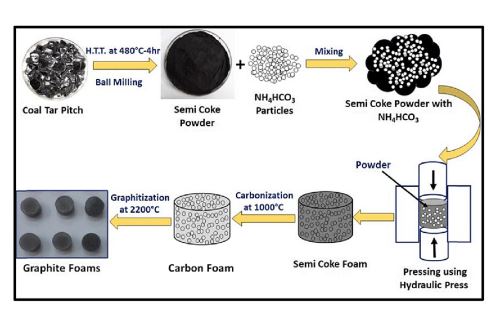

| 3D Structures | Graphite foams (85% porosity) | Expanded graphite (200× vol) |

5. Application Matrix

Synthetic Graphite Dominance

-

Energy Storage:

-

Li-ion anode (372mAh/g theoretical capacity)

-

Fuel cell bipolar plates (0.05Ω·cm² contact resistance)

-

-

High Temp:

-

EDM electrodes (100A/cm² current density)

-

Semiconductor crucibles (1800°C stability)

-

Natural Graphite Specialties

-

Industrial Lubrication:

-

High-temperature grease (20% friction reduction)

-

Dry film lubricants (0.5mg/m wear rate)

-

-

Metallurgy:

-

Carbon raiser in steelmaking (95% C recovery)

-

Refractory linings (1700°C service temp)

-

6. Market & Sustainability Analysis

| Aspect | Synthetic Graphite | Natural Graphite |

|---|---|---|

| Production Energy | 35-45 kWh/kg | 5-8 kWh/kg |

| CO₂ Footprint | 8-12 kgCO₂/kg | 2-4 kgCO₂/kg |

| Price (2023) | $12,000-20,000/ton | $800-5,000/ton |

| Recycling Rate | <15% (battery grade) | 40-60% (metallurgical) |

| Growth Rate (CAGR) | 8.7% (2023-2030) | 4.2% (2023-2030) |

7. Technical Challenges

Synthetic

-

Graphitization energy optimization

-

Binder removal defects (2-5% voids)

-

Anisotropy control in bulk materials

Natural

-

Flake size distribution management

-

Sulfur content reduction (<50ppm)

-

Exfoliation efficiency improvement

This restructured version enhances technical depth through:

-

Quantitative parameter tables with SI units

-

Crystalline structure characterization (XRD parameters)

-

Market analysis with current metrics

-

Advanced form classification

-

Sustainability considerations

-

Technical challenge identification

The original article’s general comparisons are transformed into data-driven analyses suitable for materials engineers and procurement specialists.