What do we do?

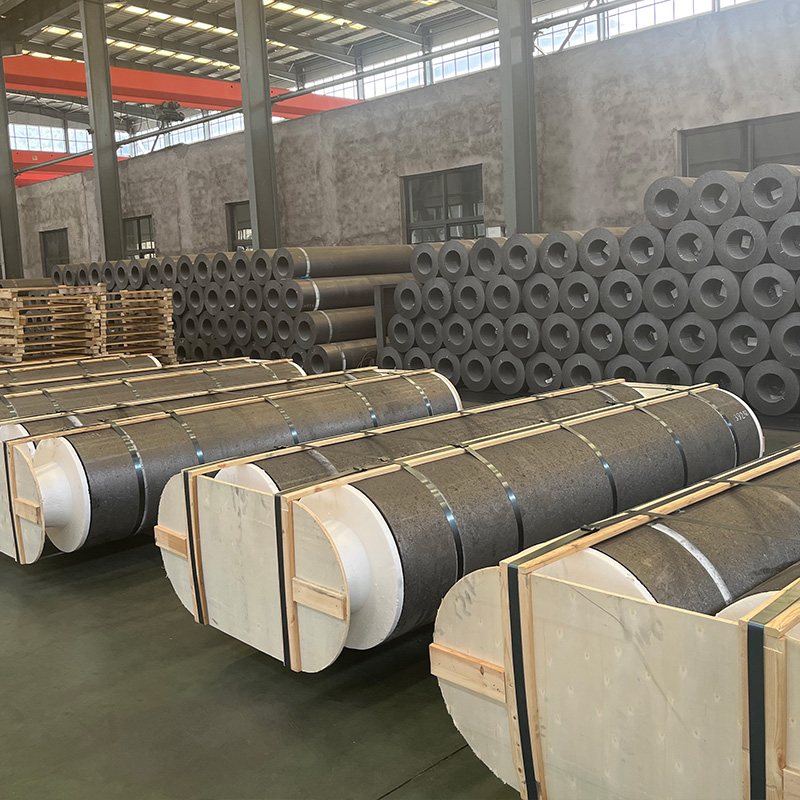

Our main products are UHP/HP/RP Graphite electrodes, Graphitized Petroleum Coke, Calcined Petroleum Coke and other Graphite products. Our factory is located in the “Changxiang Industrial Park” of North China Carbon Base in Shanxi and Liaoning Province. The entire factory covers an area of 88,000 square meters, with the construction area of 42,800 square meters. There are 280 employees, including 39 technical staff. The company’s total assets exceed 600 million and annual comprehensive production capacity has already exceeded 50,000 tons.

What problems can our graphite electrode products solve?

If you are engaged in high-temperature manufacturing industries such as steel smelting, electrolytic aluminum, ferroalloys, calcium carbide, industrial silicon and yellow phosphorus smelting, our graphite electrode products can solve your problems.

Why is graphite electrode an ideal industrial material?

Graphite electrodes are resistant to high temperatures, have high conductivity, are resistant to oxidation, have high mechanical strength, and have low impurity content. They are widely used in electric furnace steelmaking and steel refining outside the furnace, as well as the smelting of industrial raw materials such as industrial silicon, yellow phosphorus, glass, and silicon carbide. It is precisely because of these advantages and wide applicability that graphite electrodes are ideal industrial materials.

Advantages of graphite electrodes

1. Graphite material has better electrochemical stability. This type of electrode has a lower loss rate.

2. Graphite electrode is easy to process, and its processing speed is significantly faster than copper electrode.

3. Graphite is light in weight and has good thermaland electrical conductivity.

What are the categories of graphite electrodes?

According to the capacity of the electric furnace, the power load of the transformer, the difference in the raw materials used in the production of the electrode, and the physical and chemical indicators of the finished electrode, graphite electrodes are divided into three categories:

>> View UHP Graphite Electrode products

>> View HP Graphite Electrode products

>> View RP Graphite Electrode products

Why choose us?

We have ISO/SGS/MSDS certificates, authoritative and trustworthy

We have participated in industry exhibitions and cooperated with customers many times.

We use wooden frames and steel bars for packaging to ensure safe transportation of goods.

If you have a demand for graphite electrodes, contact us now!