1 Overview of Graphite Machining

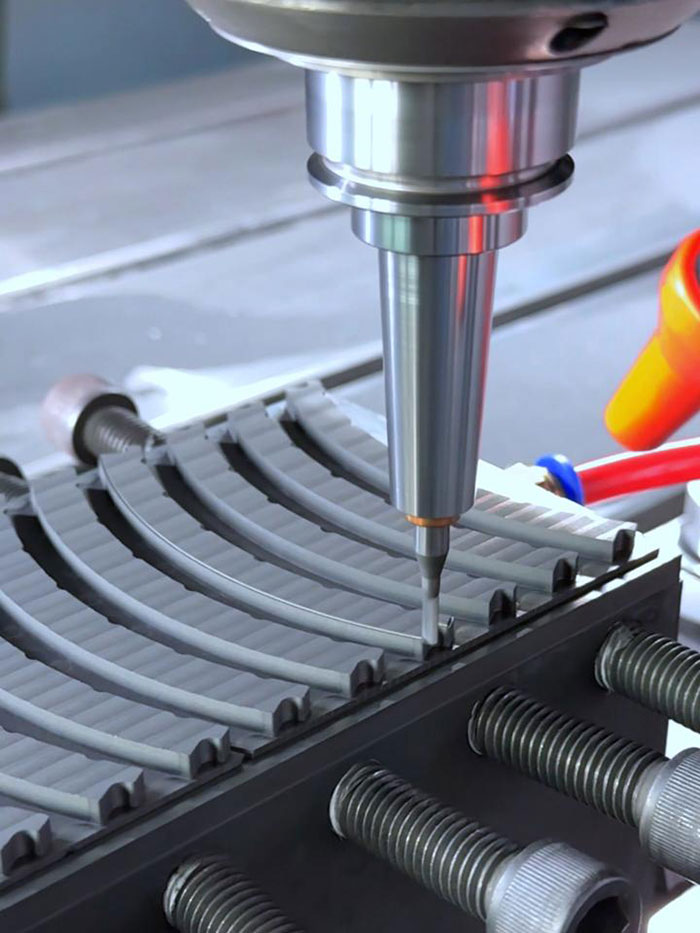

Graphite machining is a specialized manufacturing process that transforms graphite materials into precise components for industrial applications. Unlike conventional metal machining, graphite processing requires unique techniques and tools due to its combination of properties: excellent electrical and thermal conductivity, corrosion resistance, and high-temperature stability, coupled with low hardness but high abrasiveness. This unique combination enables graphite components to perform in demanding environments where other materials would fail, but also presents distinct machining challenges that require specialized expertise to overcome effectively.

2 The Critical Importance of Precision Graphite Machining

2.1 Maximizing Material Properties

Precision graphite machining unlocks the full potential of graphite’s unique properties. Through specialized machining techniques, manufacturers can create components that maintain graphite’s inherent electrical conductivity (ranging from 3-5 × 10⁵ S/m for various grades) while achieving dimensional accuracies within ±0.01 mm for critical applications. This precision ensures optimal performance in applications ranging from EDM electrodes to semiconductor processing components.

2.2 Economic Efficiency

Advanced machining strategies significantly reduce material waste – a critical factor given the substantial cost of high-purity graphite (up to $100/kg for nuclear-grade materials). Modern CNC graphite machining centers can achieve material utilization rates exceeding 85% compared to 60-70% with conventional methods, directly impacting production economics.

2.3 Application-Specific Optimization

Different industries require specialized graphite characteristics. The aerospace sector needs components with exceptional thermal stability (withstanding up to 3000°C in inert atmospheres), while electronics manufacturing demands ultra-high-purity graphite (99.9995% carbon content) with precise dimensional stability. Precision machining enables customization of graphite properties for these specific applications.

3 Types of Machinable Graphite Materials

3.1 Natural Graphite

-

Cost efficiency: Approximately 30-40% less expensive than synthetic alternatives

-

Typical applications: Crucibles, lubricants, and basic electrical components

-

Limitations: Inconsistent particle distribution (10-100 μm range) causing potential tool wear variations and lower purity levels (94-98% carbon content)

-

Machining challenges: Higher tendency for dust generation and edge chipping during fine detailing

3.2 Synthetic Graphite

-

Enhanced properties: Controlled microstructure with particle sizes from 1-20 μm and higher purity levels (99.95-99.999% carbon)

-

Superior machinability: More predictable tool wear patterns and better surface finish capabilities (achieving Ra < 0.4 μm)

-

Isotropic varieties: Provide uniform properties in all directions, critical for complex components

-

Applications: Semiconductor processing components, EDM electrodes, nuclear reactors, and high-temperature furnaces

3.3 Advanced Composite Graphites

Recent developments include graphite-based composites with enhanced properties:

-

Silicon-impregnated graphite: 40% higher hardness and improved oxidation resistance

-

Carbon-carbon composites: Superior strength-to-weight ratio for aerospace applications

-

Coated graphites: Specialized surface treatments reducing permeability and improving wear resistance

Table: Comparison of Graphite Types for Machining

| Property | Natural Graphite | Standard Synthetic | High-Purity Synthetic |

|---|---|---|---|

| Carbon Content | 94-98% | 99.0-99.5% | 99.95-99.999% |

| Average Particle Size | 10-100 μm | 10-20 μm | 1-10 μm |

| Flexural Strength | 20-35 MPa | 40-80 MPa | 60-120 MPa |

| Electrical Resistivity | 8-12 μΩ·m | 6-9 μΩ·m | 5-7 μΩ·m |

| Cost Factor | 0.6-0.7 | 1.0 | 1.5-3.0 |