Regular Power RP Graphite Electrode 100-1400mm for electric arc furnace and LF

Graphite electrodes exhibit low electrical resistance, facilitating optimal energy transfer, and possess adequate mechanical strength, ensuring reliable performance during steelmaking processes, especially in smaller-scale operations

Applications

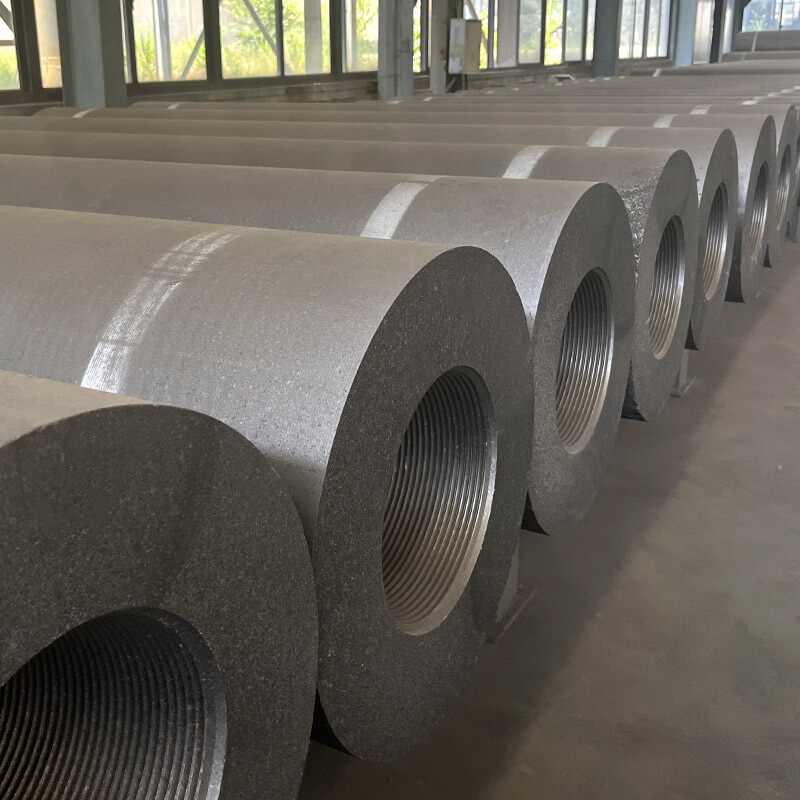

The main raw material used in the production of the RP graphite electrode is petroleum coke and coal tarregular pitch. For regular power graphite electrode production, a small amount of pitch coke can be added. The sulfur content of petroleum coke and asphalt coke cannot exceed 0.5%.It is allowed to carry the current density less than 18A/cm2. Generally it is used in regular power electric arc furnace for steel making.

Regular ower RP graphite electrodes are used in electric arc furnace (EAF) and ladle furnace (LF) for steel production, ferroalloy production, silicon metal production and smelting processes. RP graphite electrode using ordinary grade petroleum coke, the graphitization temperature is low, the graphite electrode produced has high resistivity, large linear expansion coefficient, and poor thermal shock resistance, so the allowable current density is low. RP graphite electrode uitable for crude steel smelting.

The application of regular power graphite electrodes in steelmaking involves their use within electric arc furnaces to conduct electricity and generate high temperatures, melting scrap steel or raw iron materials for steel production and refining.

Specification for BENHONG Graphite electrode

| Items | Unit | Nominal diameter(mm) | ||||

| 100~200 | 250~300 | 350~600 | 780-1400 | |||

| Specific resistance | Electrode | μΩ·m | 7.5~8.5 | 7.5~8.5 | 7.5~8.5 | 8.5~10.5 |

| Nipple | 5. 8~6.5 | 5. 8~6.5 | 5. 8~6.5 | 5.8~6.5 | ||

| Transverse strength | Electrode | MPa | ≥10.0 | ≥9.0 | ≥8.5 | ≥7.0 |

| Nipple | ≥16.0 | ≥16.0 | ≥16.0 | ≥16.0 | ||

| Elastic modulus | Electrode | GPa | ≤9.3 | ≤9.3 | ≤9.3 | ≤12.0 |

| Nipple | ≤13.0 | ≤13.0 | ≤13.0 | ≤13.0 | ||

| Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

| Nipple | ||||||

| Bulk density | Electrode | g/m³ | 1.55~1.64 | 1.55~1.64 | 1.55~1.63 | 1.55~1.63 |

| Nipple | ≥1.74 | ≥1.74 | ≥1.74 | ≥1.74 | ||

| C.T.E | Electrode | 10-6℃ | ≤2.4 | ≤2.4 | ≤2.4 | ≤2.4 |

| Nipple | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ||

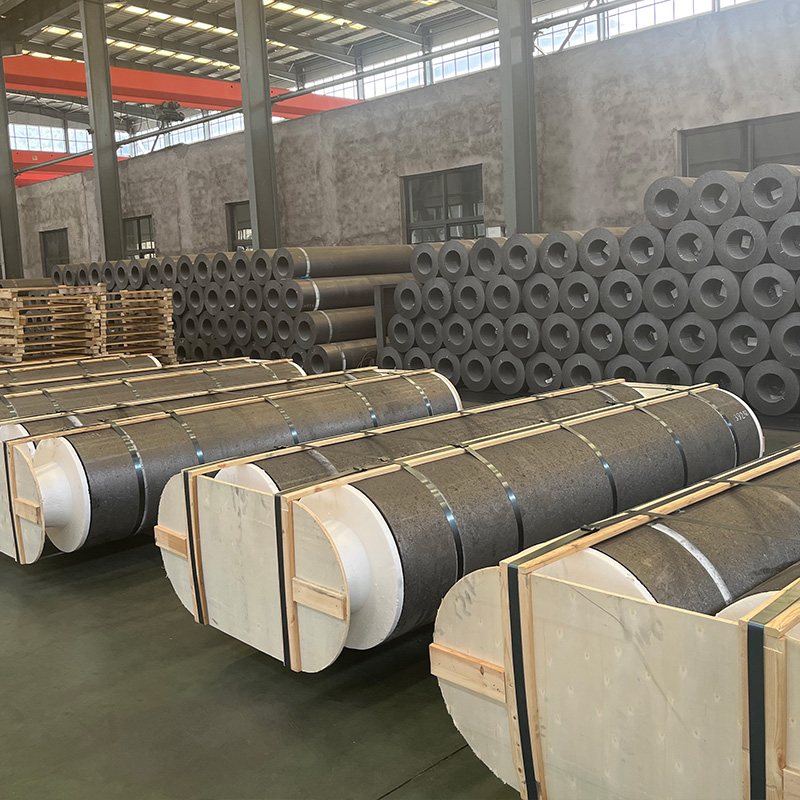

Production facilities

Production process

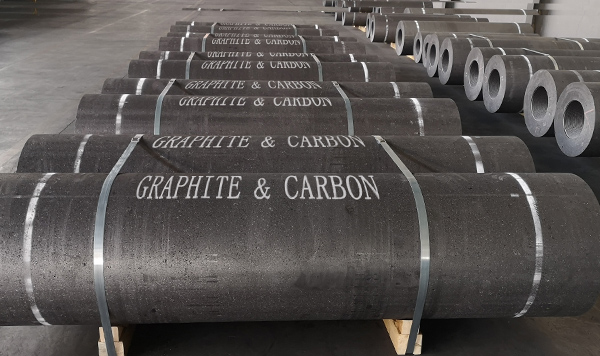

Packaging

About us

Our business principles include good market reputation, honesty and trustworthiness. Integrity is the foundation of BENHONG, while quality is the life of the company.

1.30 years of production experience has convinced us that this is our careers, not just a business.

2.We have all the certificates needed in the field:ISO/SGS/MSDS.

3.Our team is honest, united and has a high service spirit.

4.We have establaished cooperation with Saudi Arabia,Iran,India, Turkey, Brazil, Russia and other countries.

5.Customer as the core of the complete after-sales service.

6.The repeat purchase rate exceedns 95%.