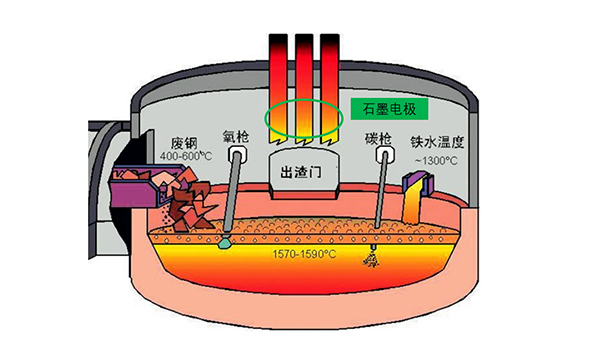

Reducing electrode oxidation consumption is a key issue in the electric arc furnace steelmaking process, because electrode oxidation will increase steelmaking costs, affect process efficiency, and reduce electrode life. The following are some main measures to reduce electrode oxidation consumption:

Proper electrode selection:

Choose high-quality electrode materials, such as graphite electrodes or graphite blocks, to reduce the electrode’s tendency to oxidize. These electrodes have good heat resistance and oxidation resistance and can operate stably at high temperatures.

Optimize the electrode cooling system:

Ensure the electrode cooling system is operating effectively to reduce the temperature of the electrode. Cooling water circulation and temperature control are critical to maintaining low electrode temperatures, reducing the chance of oxidation.

Control the electrode descent speed:

Control the electrode descent speed to avoid electrode oxidation caused by rapid descent. An excessively fast descent rate may trigger oxidation reactions, resulting in increased electrode consumption.

Maintaining a Proper Furnace Atmosphere:

Maintaining a reducing furnace atmosphere is the key to reducing electrode oxidation. By controlling the input of oxygen and nitrogen, the oxygen concentration can be reduced and the oxidation of the electrode reduced.

Reduce arc burning time:

Make sure the arc burning time is not too long, as prolonged arcing will increase the risk of oxidation of the electrode. By controlling the arc intensity and burning time, the degree of oxidation of the electrode can be reduced.

Electrode Coatings and Protective Layers:

In some cases, coatings or protective layers may be applied to the electrode surface to reduce oxidation. These coatings provide additional protection and extend the life of the electrodes.

Regular inspection and maintenance:

Regularly check the condition of the electrode, including wear and oxidation of the electrode head, and the connection between the electrode and the electrode clamp. Prompt repair and replacement of damaged parts can reduce the effects of oxidation.

Optimized arc stability:

A stable arc helps reduce electrode oxidation. Using a high-quality arc control system to ensure arc stability can reduce the risk of electrode oxidation.

Control the arc temperature:

Control the arc temperature by adjusting the intensity and voltage of the arc to reduce the oxidation rate of the electrode.

Optimize electrode shape:

Proper electrode shape design can reduce electrode oxidation. Choose appropriate electrode diameter and shape to minimize electrode loss.

By taking these measures, electrode oxidation consumption can be effectively reduced, the efficiency of electric arc furnace steelmaking can be improved, costs can be reduced, and electrode life can be extended. This is crucial for steel manufacturing in industrial production.